Cambridge Underground 1979 pp 40-45

HOT RACKS

A Review of Thermal Improvements to the Standard Rappel Rack

One of the greatest criticisms levelled against racks is their limited

heat sinking characteristics. Generally the rack is considered poor, or only

just adequate, when it comes to staying cool on long descents (1,2). However

it is in this field that a number of significant improvements can be made.

For cavers of similar weights, abseiling at similar speeds on a given

pitch, the energy involved (almost all of which is heat energy) is a

constant. The temperature that the descender attains during the abseil,

however, is not, and depends on several variables. These include the

environment - the ease with which heat can be dissipated to the surrounding

air, krabs, hands, the rope (nylon conducts heat away better than terylene;

and a wet rope, with its higher effective specific heat, can absorb more heat

energy whilst staying cooler than a dry rope); and very important, as has

been shown by Isenhart (3) and Eavis (4), the descender design.

Descenders have better temperature characteristics (meaning that the

device takes longer to heat up) the larger their mass is. A good descender

should also have good thermal conductivity as heat needs to be transferred

quickly from 'hot spots' ie. the rope/device contact areas. The ideal

descender should also have a large surface area, giving extensive contact

with the environment, leading to better heat dissipation.

Standard racks with 18mm diameter cylindrical duralumin bars generally

have a reasonably high mass, and a good surface area, but fall down

(figurativly speaking) when it comes to the dissipation of the heat produced

at hot spots. The duralumin bars of the rack have a relatively high specific

heat and thermal conductivity, but are unfortunately isolated from one

another by the steel frame, which is a relatively poor conductor of heat. To

solve, or at any rate ease, the problems of 'hot racks', the following can be

done:

1) Altering the Brake Bar Material

Duralumin alloys have high specific heat, and are therefore a fairly

suitable choice already. And when considering other brake bar materials the

problem of wear should also be considered. Cole (2) quotes some American

cavers as having tried hollow stainless steel bars, which would be excellent

from the wear point of view, but would be worse than the duralumin bars for

heating problems, because of the steel's relatively low specific heat and

conductivity failing to outweigh the increased surface area of a hollow bar.

Some varieties of phosphor-bronze are another possibility. The heating and

wear characteristics of this material would be excellent. The alloy is rather

heavy however, and since it is copper based, the subtle complication of

bimetallic corrosion (copper in contact with steel enhances the corrosion of

the latter) may occur. The effect or speed of this corrosion reaction would

be very difficult to judge. To be on the safe side it would seem sensible,

when dealing with the aggressive environment of a cave, to avoid the direct

combination of phosphor-bronze bars with anything but the very best quality

stainless steel frames. In conclusion, I think duralumin is probably the best

bar material still, for all applications except the most muddy, where wear

considerations are uppermost.

2) Altering the Brake Bar Size

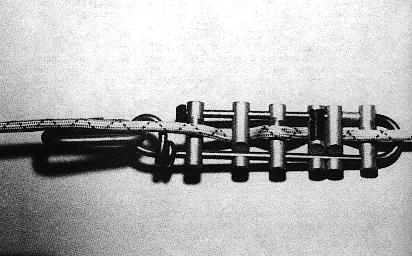

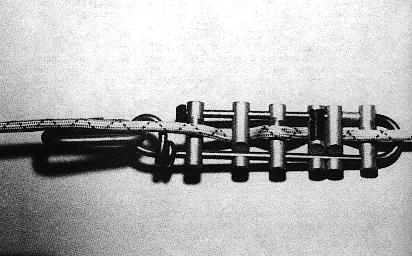

Fig.1 Close up of rope/bar contact

Obviously bigger brake bars have a bigger thermal

capacity and therefore bigger bars are better, and square bars perform better

than round (3,5). But to increase the bar size at random is wasteful -

ideally bar sizes should be in proportion to the heat generated by each.

Here, the American theoreticians have had a field day, and for the

mathematically minded Storrick (6) analysed the situation as follows. The

heat generated by a bar is a function of the contact angle of the rope and

the friction between the two. The heat produced is then roughly proportional

to the consequent difference in rope tension above and below the bar (Fig.

1).

Obviously bigger brake bars have a bigger thermal

capacity and therefore bigger bars are better, and square bars perform better

than round (3,5). But to increase the bar size at random is wasteful -

ideally bar sizes should be in proportion to the heat generated by each.

Here, the American theoreticians have had a field day, and for the

mathematically minded Storrick (6) analysed the situation as follows. The

heat generated by a bar is a function of the contact angle of the rope and

the friction between the two. The heat produced is then roughly proportional

to the consequent difference in rope tension above and below the bar (Fig.

1).

The governing equation is:

T2 = T1 exp(-µA)

where T1 is the tension in the rope above the bar,

T2 is the tension below the bar, µ is the coefficient of

friction (about 0.25 in this situation), and A is the rope/bar contact angle

in radians. Out of the mathematics comes the bar temperature distribution

shown in Fig. 2.

Fig.2 Relative bar temperatures

The salient point here I think is probably a non-intuitive one

- the second bar gets hotter than the first. This is due to the fact that the

top bar has a smaller rope contact angle than the other bars, and this

produces a smaller rope tension difference, and therefore a smaller heat

production than bar two. The best solution therefore seems to be to make rack

bars of relative sizes corresponding to the given temperature distribution.

However the major disadvantage of this is that the bars would become specific

to a particular position on the rack, and there would be no possibility of

swopping worn top bars for relatively new bottom ones. Therefore, to keep the

bars universal, a better solution (6) appears to be to 'double up' the bars

as shown in Fig. 3. For most drops just having the second and third bars

facing the same way should nicely improve the effective mass and surface area

of the new 'second' bar, without decreasing the controlling friction

appreciably. Doubling up the top bar too would further improve the heat

sinking characteristics of the rack, but would probably result in too radical

a reduction in controlling friction.

The salient point here I think is probably a non-intuitive one

- the second bar gets hotter than the first. This is due to the fact that the

top bar has a smaller rope contact angle than the other bars, and this

produces a smaller rope tension difference, and therefore a smaller heat

production than bar two. The best solution therefore seems to be to make rack

bars of relative sizes corresponding to the given temperature distribution.

However the major disadvantage of this is that the bars would become specific

to a particular position on the rack, and there would be no possibility of

swopping worn top bars for relatively new bottom ones. Therefore, to keep the

bars universal, a better solution (6) appears to be to 'double up' the bars

as shown in Fig. 3. For most drops just having the second and third bars

facing the same way should nicely improve the effective mass and surface area

of the new 'second' bar, without decreasing the controlling friction

appreciably. Doubling up the top bar too would further improve the heat

sinking characteristics of the rack, but would probably result in too radical

a reduction in controlling friction.

An important safety note with this 'doubled up' bar

configuration is the need to avoid threading the bottom bars back to front

when the top ones have been threaded correctly. The best reminder

'periodically suggested and consistently ignored' is bright tape across the

back of the bars.

An important safety note with this 'doubled up' bar

configuration is the need to avoid threading the bottom bars back to front

when the top ones have been threaded correctly. The best reminder

'periodically suggested and consistently ignored' is bright tape across the

back of the bars.

3) Increasing the Inter-bar Conductivity

The steel frame, being a relatively poor heat conductor, thermally

isolates the bars' from one another. In theory, the bars could be 'thermally

joined' by the placing of 'spacers'. A hollow cylinder of good conductivity

metal can be threaded onto the locknut side of the frame to lie between the

first and second bars. For this purpose the spacer is best made of duralumin.

Duralumin has good conductivity, and will not suffer from bi-metallic

corrosion problems with the steel frame. Brass is suspect here, and since it

has a lower conductivity than duralumin anyway, it is best avoided.

Montgomery (7) implies that in practice spacers increase the conductivity

between the bars , and Isenhart (8) has this to say about the incorporation

of spacers in his super rack, "The aluminium spacers between the top and

second bars not only keep the upper bars from pinching together and

overheating, but also act as heat transfer links between them and help

maintain the temperature equilibrium of the super rack." However, since

spacer/bar contacts are likely to be poor, I think any 'thermal linking' will

be minimal. The idea is however not a waste of time. Besides preventing any

pinching of the top two bars of the device, Storrick (6) correctly points out

that spacer bars can be made long enough to reduce the rope contact angle of

the bars that it separates This reduces heat production, and so the rack runs

cooler. Unfortunately, control friction will also be reduced by spacers, but

if they are not made too long this should not be a serious problem. An

optimum length seems to be about 20mm. Since the main function of the spacers

seems to be in lowering the rope contact angle, the material of which it is

made may as well not be a conductor. Lengths of old garden hose may prove

suitable if of an adequate stiffness.

Fig.4 The modified rack

In conclusion then, the

improved rack would appear as shown in Fig. 4. Square bars would be an

additional thermal improvement of the rack, but this must be weighed against

the increased bulk of the device. The rack illustrated, with the

modifications shown, I have found has a slightly lower control friction than

the standard format rack. This reduction is not critical however, and on the

bright side, the modified format does handle detectably cooler.

In conclusion then, the

improved rack would appear as shown in Fig. 4. Square bars would be an

additional thermal improvement of the rack, but this must be weighed against

the increased bulk of the device. The rack illustrated, with the

modifications shown, I have found has a slightly lower control friction than

the standard format rack. This reduction is not critical however, and on the

bright side, the modified format does handle detectably cooler.

Nick Thorne

References:

(1) Montgomery, N.R. 1976 'The Rack v. Whaletail -

A Second Opinion' Descent 34

(2) Cole, J. 1977 'The Rack v. Whaletail' Descent 36

(3) Isenhart, K. 1975 'Temperature Studies of Rappelling Devices'

Nylon Highway 4

(4) Eavis, A.J. 1977 'Thermal Properties of Abseiling Devices'

Proc. I.S.C. No. 7. Sheffield 1977

(5) Seaman, E. 1978 'Brake Bar Design' Nylon Highway 9

(6) Storrick, G. 1978 'Design of Specialty Racks' Nylon Highway 9

(7) Montgomery, N.R. 1977 'Single Rope Techniques'

(8) Isenhart, K. 1974 'The Super Rack' Nylon Highway 1

Index to Cambridge Underground

Index to Cambridge Underground

Table of Contents for Cambridge Underground 1979

Table of Contents for Cambridge Underground 1979

Back to CUCC top page

Back to CUCC top page

Obviously bigger brake bars have a bigger thermal

capacity and therefore bigger bars are better, and square bars perform better

than round (3,5). But to increase the bar size at random is wasteful -

ideally bar sizes should be in proportion to the heat generated by each.

Here, the American theoreticians have had a field day, and for the

mathematically minded Storrick (6) analysed the situation as follows. The

heat generated by a bar is a function of the contact angle of the rope and

the friction between the two. The heat produced is then roughly proportional

to the consequent difference in rope tension above and below the bar (Fig.

1).

Obviously bigger brake bars have a bigger thermal

capacity and therefore bigger bars are better, and square bars perform better

than round (3,5). But to increase the bar size at random is wasteful -

ideally bar sizes should be in proportion to the heat generated by each.

Here, the American theoreticians have had a field day, and for the

mathematically minded Storrick (6) analysed the situation as follows. The

heat generated by a bar is a function of the contact angle of the rope and

the friction between the two. The heat produced is then roughly proportional

to the consequent difference in rope tension above and below the bar (Fig.

1). The salient point here I think is probably a non-intuitive one

- the second bar gets hotter than the first. This is due to the fact that the

top bar has a smaller rope contact angle than the other bars, and this

produces a smaller rope tension difference, and therefore a smaller heat

production than bar two. The best solution therefore seems to be to make rack

bars of relative sizes corresponding to the given temperature distribution.

However the major disadvantage of this is that the bars would become specific

to a particular position on the rack, and there would be no possibility of

swopping worn top bars for relatively new bottom ones. Therefore, to keep the

bars universal, a better solution (6) appears to be to 'double up' the bars

as shown in Fig. 3. For most drops just having the second and third bars

facing the same way should nicely improve the effective mass and surface area

of the new 'second' bar, without decreasing the controlling friction

appreciably. Doubling up the top bar too would further improve the heat

sinking characteristics of the rack, but would probably result in too radical

a reduction in controlling friction.

The salient point here I think is probably a non-intuitive one

- the second bar gets hotter than the first. This is due to the fact that the

top bar has a smaller rope contact angle than the other bars, and this

produces a smaller rope tension difference, and therefore a smaller heat

production than bar two. The best solution therefore seems to be to make rack

bars of relative sizes corresponding to the given temperature distribution.

However the major disadvantage of this is that the bars would become specific

to a particular position on the rack, and there would be no possibility of

swopping worn top bars for relatively new bottom ones. Therefore, to keep the

bars universal, a better solution (6) appears to be to 'double up' the bars

as shown in Fig. 3. For most drops just having the second and third bars

facing the same way should nicely improve the effective mass and surface area

of the new 'second' bar, without decreasing the controlling friction

appreciably. Doubling up the top bar too would further improve the heat

sinking characteristics of the rack, but would probably result in too radical

a reduction in controlling friction. An important safety note with this 'doubled up' bar

configuration is the need to avoid threading the bottom bars back to front

when the top ones have been threaded correctly. The best reminder

'periodically suggested and consistently ignored' is bright tape across the

back of the bars.

An important safety note with this 'doubled up' bar

configuration is the need to avoid threading the bottom bars back to front

when the top ones have been threaded correctly. The best reminder

'periodically suggested and consistently ignored' is bright tape across the

back of the bars. In conclusion then, the

improved rack would appear as shown in Fig. 4. Square bars would be an

additional thermal improvement of the rack, but this must be weighed against

the increased bulk of the device. The rack illustrated, with the

modifications shown, I have found has a slightly lower control friction than

the standard format rack. This reduction is not critical however, and on the

bright side, the modified format does handle detectably cooler.

In conclusion then, the

improved rack would appear as shown in Fig. 4. Square bars would be an

additional thermal improvement of the rack, but this must be weighed against

the increased bulk of the device. The rack illustrated, with the

modifications shown, I have found has a slightly lower control friction than

the standard format rack. This reduction is not critical however, and on the

bright side, the modified format does handle detectably cooler.